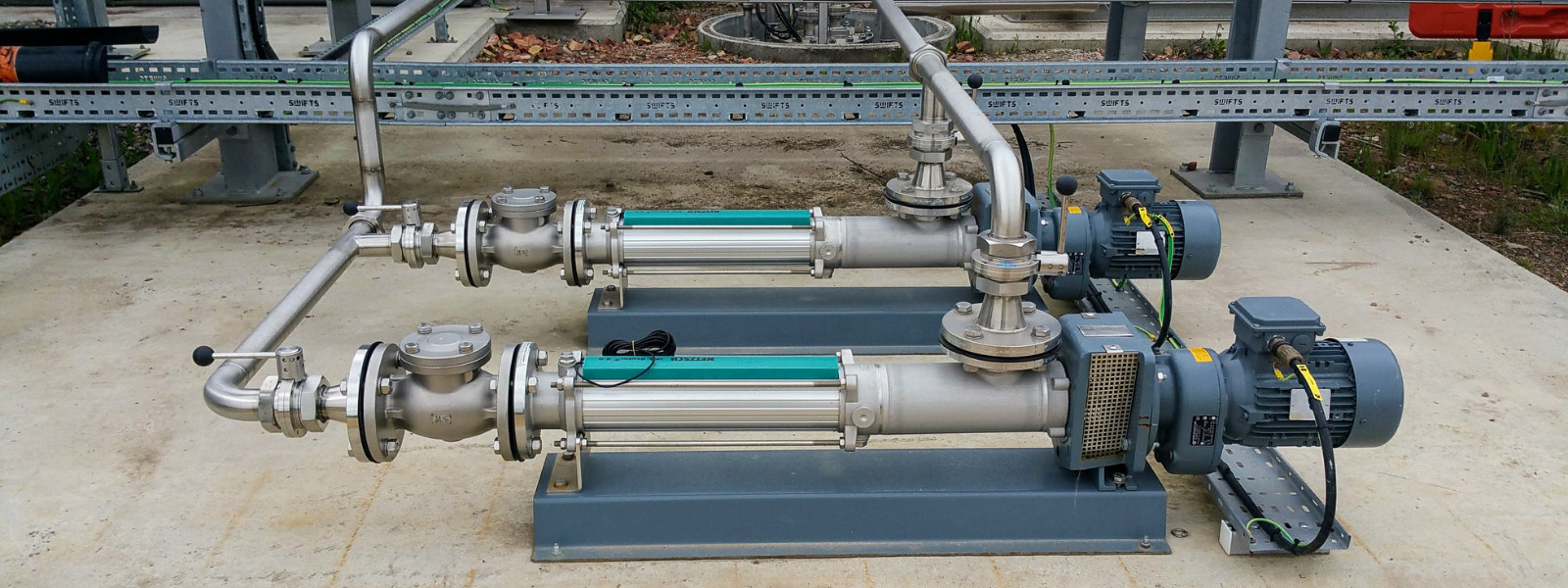

Progressive Cavity Pumps

PolyPump offer a wide range of Progressive Cavity Pumps commonly used for pumping non-Newtonian fluids where a centrifugal pump would struggle. The two conveying elements are the rotor and the fixed stator, in which the rotor eccentrically turns.

Geometries / Joint types

- S Geometry (12bar Double Stage ) very smooth pumping – large solids

- L Geometry ( 6bar Single Stage ) High flow rates - Good volumetric efficiency & abrasion resistant

- D Geometry ( 12bar Double stage ) Used for dosing due to almost no pulsation – High pressures / flow

- P Geometry ( 6bar Single Stage ) Used for dosing due to almost no pulsation – High pressures / flow

- Pin joint, gear joint & cardan Universal Joint

Types of Progressive Cavity Pump

- Standard PC

- Metering / Dosing

- Wide Throat / Hopper inc bridge breaker

- Food / Pharmaceutical

- Immersible / Submerged

Rotary Lobe Pumps

Often used within the dairy, food manufacturing, cosmetics and pharmaceutical industries due to how they handle low or high viscosity product. When there are products containing fragile solids the free passage size, non-contacting, and rotation speed of pump ensure product remains undamaged. An example is transferring yogurt with soft fruits.

Rotary lobe pumps are known for their corrosion resistance, reliability, high efficiency and ease of cleaning /maintenance ( cleaning in place CIP / steam in place SIP ) there are 3 types of lobes, Single Lobe, bi Lobe & tri Lobe. An added benefit of a rotary lobe pump is that it can be ran in reverse.

Applications

- Soaps / Shampoos / Face Creams / Pastes

- Paints / Varnishes / Dyes

- Yogurt / Milk / Cream

- Mortars / Plaster / Paper coatings

- Chocolate / Sauces / Jam / Syrup

Air Operated Diaphragm Pumps

AOD or AODD (air-Operated double-diaphragm) pumps are used for low pressure applications and shifting sludges, shear sensitive fluids. They are all most leak free as they would require both diaphragms to fail. To prevent this you can install leak detection sensors which are a worth while add when purchasing a new AOD pump. With no internal seals or moving parts that require lubricating it be ran dry indefinitely without damage. Another benefit they can self-prime and capable of a suction lift of up to 8m.

Applications

- Paint, solvents, inks and dyes

- Glues & resins

- Oils and glycol transfer

Peristaltic Pump

The only wetted part of a peristaltic pump is the hose itself leading to low maintenance , dry running capabilities and limited number of parts making them an engineers dream if selected correctly.

Applications

- Abrasive products- Lime milk, activated carbon, sludges and slurries

- Corrosive products- Sodium hypochlorite, ferric chloride, hydrochloric acid

- Viscous products - Water-based glues, greases, creams, resins

- Shear sensitive products- Latex, polymers and flocculants, food products

Drum / Barrel Pumps

Used to safely empty product from canisters, hobbocks, drums & IBC tanks they come in many variations for pumping all kinds of products. The fact they are used most commonly for transferring harmful chemicals many brands have ATEX certification.

Materials available

- PP (polypropylene)

- PVDF (polyvinylidene fluoride) or CPVC (chlorinated polyvinyl chloride)

- Aluminium

- 316 stainless steel

- Hastelloy